At dSeiki, we bring OEM-level engineering capability to client projects. Our fully integrated approach combines advanced simulation, precision CAD design, and state-of-the-art manufacturing understanding to deliver exceptional results.

With expertise spanning 1D simulation, computational fluid dynamics, mechanical design, assembly analysis, and advanced manufacturing processes, we transform concepts into reality with uncompromising quality and innovation.

Simulation, Design and Production Capabilities

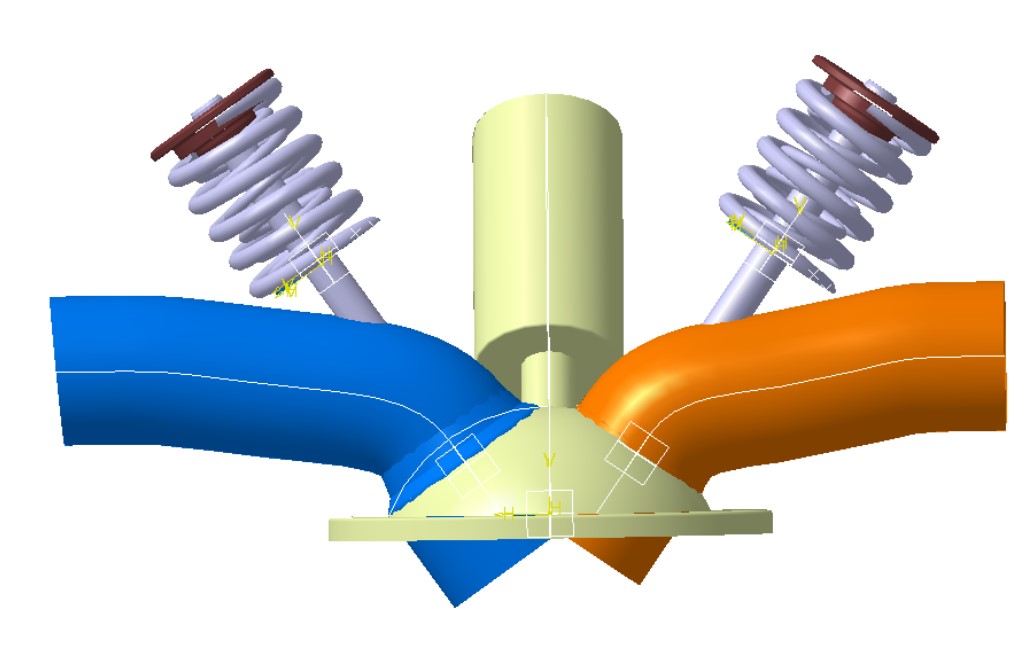

1Simulation Analysis

(OpenFOAM)

Heat transfer, fluid flow, and structural analysis can be performed to optimize designs for performance, efficiency, and reliability before committing to physical prototypes. We normally begin with comprehensive 1-D analysis using well understood calculations and techniques to generate a roadmap of potential performance. Computational fluid dynamics (CFD) analysis can be performed using OpenFOAM to drive exact port shapes. Advanced meshing techniques ensure accurate results across complex geometries.

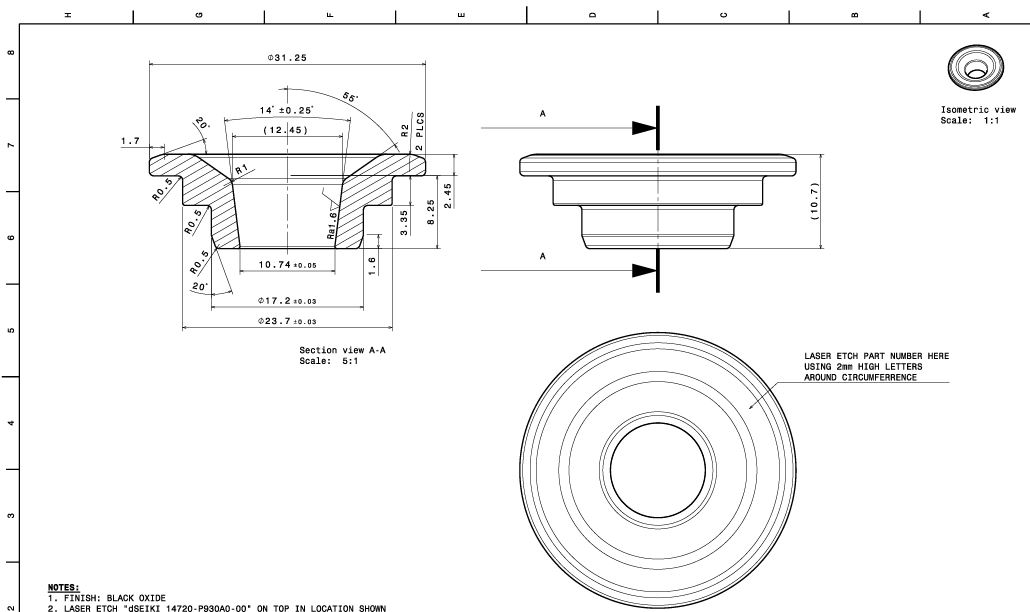

2CAD

Design

Design

(CATIA V5)

(CATIA V5)

Drawings

(CATIA V5)

Detailed 3D models are created in CATIA V5, incorporating simulation results and engineering requirements. From complete assemblies to individual components, our designs consider manufacturability, material properties, thermal management, and assembly sequences. Technical documentation ensures seamless transition to manufacturing.

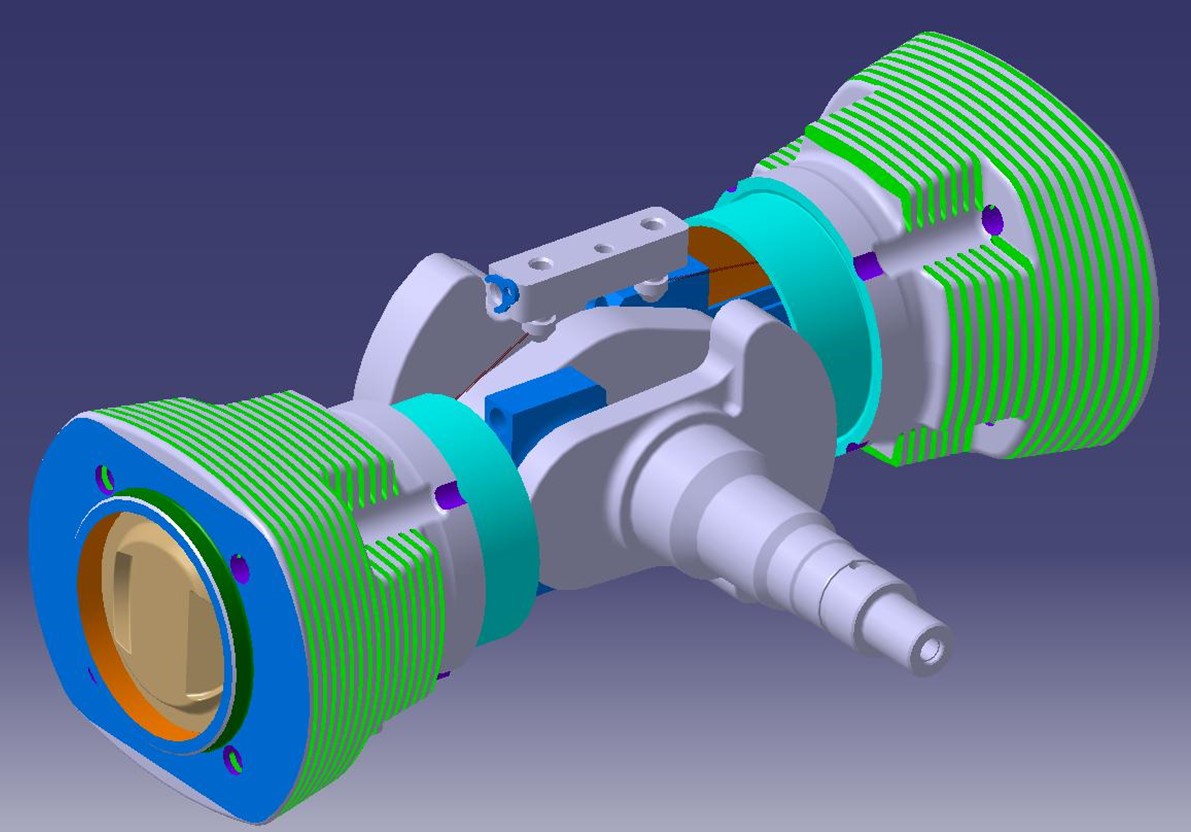

3Production

and Assembly

& Valvetrain parts

Parts

Assemblies

State of the art manufacturing processes including precision CNC machining bring designs to life with exceptional accuracy. High-performance components like pistons, cylinders, and complex assemblies are manufactured to exacting tolerances. Our understanding of Tier-1 level quality control processes ensure every part meets specifications, from surface finish to dimensional accuracy, ready for your demanding applications.

Reverse Engineering Capabilities

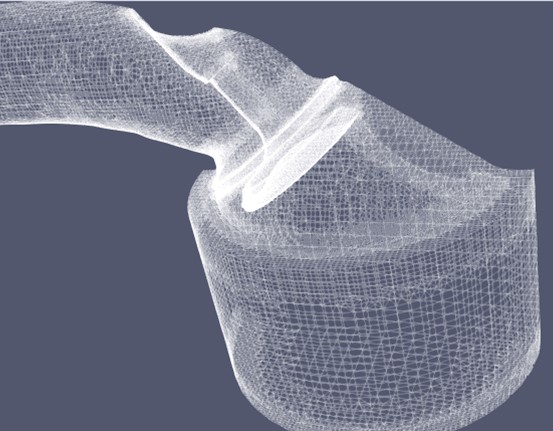

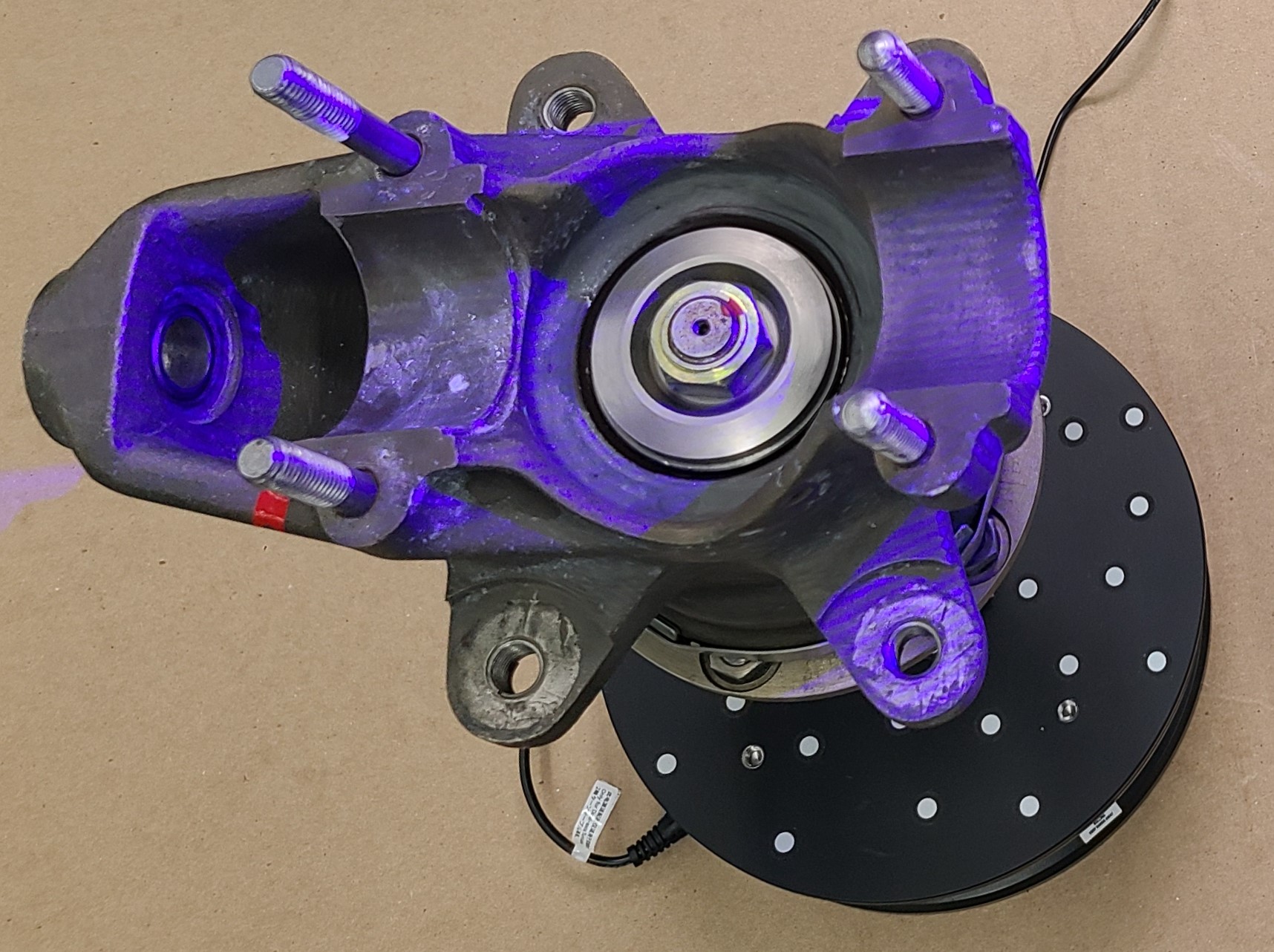

13D Object

Scanning

Scanning

3D scanning using white light and blue lasers allows us to take a unique part and capture surfaces exactly.

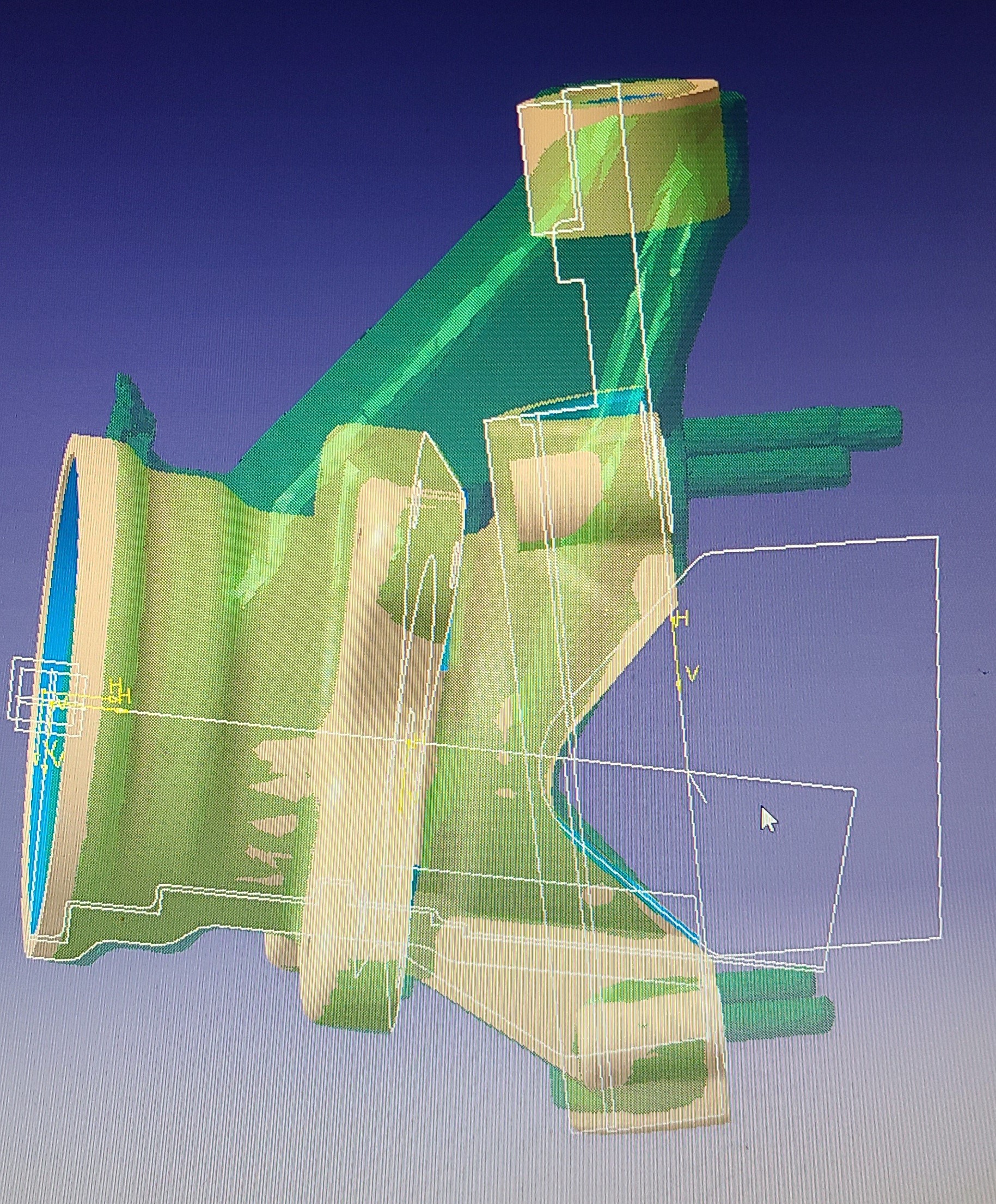

2Point Cloud

Conversion

Overlay

Once the point clouds have been captured, we convert to CAD surfaces. These can be applied directly or used to drive CAD design.

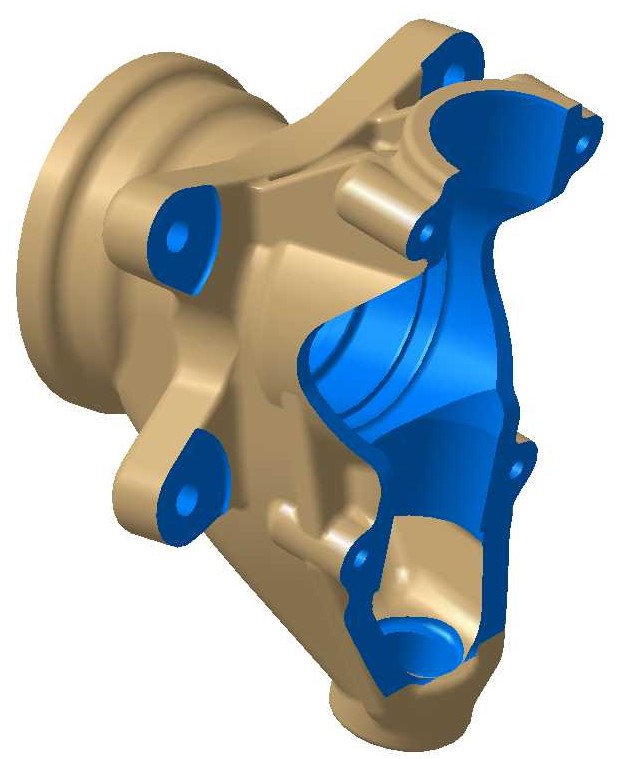

3Prepartion

for Manufacturing

Models

Native CAD surfaces are generated to ensure complete manufacturability. Since we well understand what it takes to make a part, you can be assured that your end result will be straightforward to manfuacture.

Our Commitment

dSeiki is dedicated to using our years of top level experience with the most effective tools to push the boundaries of your engineering design. Whether developing high-performance engine components, improving fluid flow systems, or complex mechanical assemblies, we deliver solutions that combine cutting-edge technology with proven manufacturing expertise.

Our integrated workflow ensures seamless progression from concept to production, minimizing development cycles while maximizing quality and innovation.